PE PP Sheet Extruder Machine,PVDF PEEK Sheet Extruder Machine,PA POM Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PE PP Board Extruder Machine,PVC Sheet Extruder Machine,PS Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,Biodegradable Sheet Machine

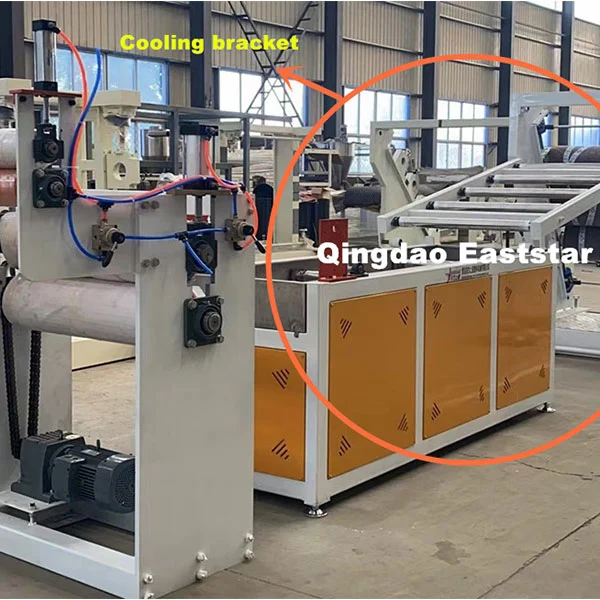

Welcome to the world of efficient, versatile, and durable doorway management. The PVC Strip Door Curtain Extruder Machine from Qingdao Eaststar Plastic Machinery Co., Ltd. is a state-of-the-art solution designed to produce high-quality PVC strip door curtains used in various industrial and commercial settings. These curtains act as flexible barriers, conserving energy by maintaining temperature control, reducing noise, blocking dust, and improving safety in high-traffic areas. Imagine a bustling warehouse where cold air escapes every time a door opens, or a food processing plant struggling with contamination—this machine empowers businesses to create custom curtains that address these challenges head-on. With over two decades of expertise, Qingdao Eaststar has engineered this extruder to deliver precision, reliability, and sustainability, making it an indispensable tool for modern facilities.

What makes the PVC Strip Door Curtain Extruder Machine a standout choice? It begins with its robust construction and innovative design. Crafted from high-grade materials, this machine ensures longevity and minimal maintenance, even under continuous operation. The advanced extrusion technology allows for precise control over strip thickness, width, and transparency, resulting in curtains that are both flexible and resilient. Users benefit from enhanced energy savings—by preventing air exchange, these curtains help cut heating and cooling costs by up to 30%. Moreover, the machine supports eco-friendly production, using recyclable PVC materials that meet international safety standards. From reducing operational downtime to offering customizable options, every aspect is tailored to boost productivity and user satisfaction.

Many businesses face issues like energy loss, poor hygiene, or safety hazards in doorways. The PVC Strip Door Curtain Extruder Machine provides a reliable solution by producing curtains that seal openings effectively. Below is a detailed parameter table highlighting key specifications to help you understand its capabilities:

| Parameter | Specification |

|---|---|

| Extrusion Output | Up to 150 kg/h |

| Strip Width Range | 100-300 mm |

| Thickness Control | 1.5-3.0 mm |

| Power Consumption | 25-40 kW |

| Machine Dimensions | 6000x1500x2000 mm |

| Material Compatibility | PVC, with options for UV-resistant additives |

These parameters ensure that the machine adapts to diverse needs, whether for heavy-industrial use or food-grade applications. By integrating smart controls, it minimizes waste and maximizes efficiency, giving you a competitive edge.

This extruder is perfect for a wide range of industries and professionals. Warehouses and logistics centers use it to maintain temperature zones and improve energy efficiency. Food processing plants and pharmaceutical companies rely on the curtains to uphold strict hygiene standards by preventing cross-contamination. Retail stores and cold storage facilities benefit from reduced energy bills and enhanced customer comfort. Even agricultural settings, such as greenhouses, utilize these curtains for climate control. Essentially, any environment requiring a flexible, durable barrier to manage air flow, noise, or safety will find this machine invaluable. Its versatility makes it a go-to for business owners, facility managers, and manufacturers seeking cost-effective, sustainable solutions.

Using the PVC Strip Door Curtain Extruder Machine brings a sense of relief and empowerment. Picture a factory manager who no longer worries about energy waste or product spoilage—thanks to these curtains, temperatures remain stable, and operational costs drop. Employees work in safer, quieter environments, free from drafts or debris. For business owners, it means higher profitability and compliance with environmental regulations. The emotional payoff is clear: reduced stress, increased pride in a well-run facility, and the confidence that comes from investing in quality. By solving everyday pain points like high utility bills or contamination risks, this machine transforms workplaces into more efficient, pleasant spaces.

Unlike many competitors, Qingdao Eaststar Plastic Machinery Co., Ltd. integrates cutting-edge automation and user-friendly features. The machine includes a PLC control system for precise adjustments, reducing the need for manual intervention. Its modular design allows for easy upgrades and maintenance, saving time and money. Additionally, the extruder supports a wider range of customizations—from color to hardness—enabling businesses to tailor curtains to specific needs. With a focus on sustainability, it uses energy-efficient motors and recyclable materials, aligning with global green initiatives. These differences stem from Qingdao Eaststar's commitment to innovation and customer-centric design, ensuring that every machine delivers superior performance and long-term value.

What is the typical lifespan of the PVC strips produced by this machine?

The strips can last 3-5 years under normal conditions, thanks to high-quality PVC and UV-resistant additives that prevent degradation from sunlight or harsh environments.

Can the machine handle different PVC formulations?

Yes, it is compatible with various PVC grades, including those with fire-retardant or anti-static properties, allowing for tailored solutions based on application requirements.

How easy is it to operate and maintain the extruder?

With automated controls and clear manuals, operators can learn quickly. Routine maintenance involves simple cleaning and part checks, with technical support available from Qingdao Eaststar.

Is training provided for new users?

Absolutely, Qingdao Eaststar offers comprehensive training sessions, either on-site or via video tutorials, to ensure smooth operation and troubleshooting.

What safety features are included?

The machine has emergency stop buttons, overload protection, and insulated components to safeguard operators and prevent accidents during production.

Can I order custom-sized curtains?

Yes, the extruder allows for adjustments in strip width and thickness, so you can produce curtains that fit unique doorway dimensions perfectly.

How does this machine contribute to energy savings?

By producing effective seals, the curtains minimize air leakage, reducing the load on HVAC systems and cutting energy consumption significantly.