PE PP Sheet Extruder Machine,PVDF PEEK Sheet Extruder Machine,PA POM Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PE PP Board Extruder Machine,PVC Sheet Extruder Machine,PS Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,Biodegradable Sheet Machine

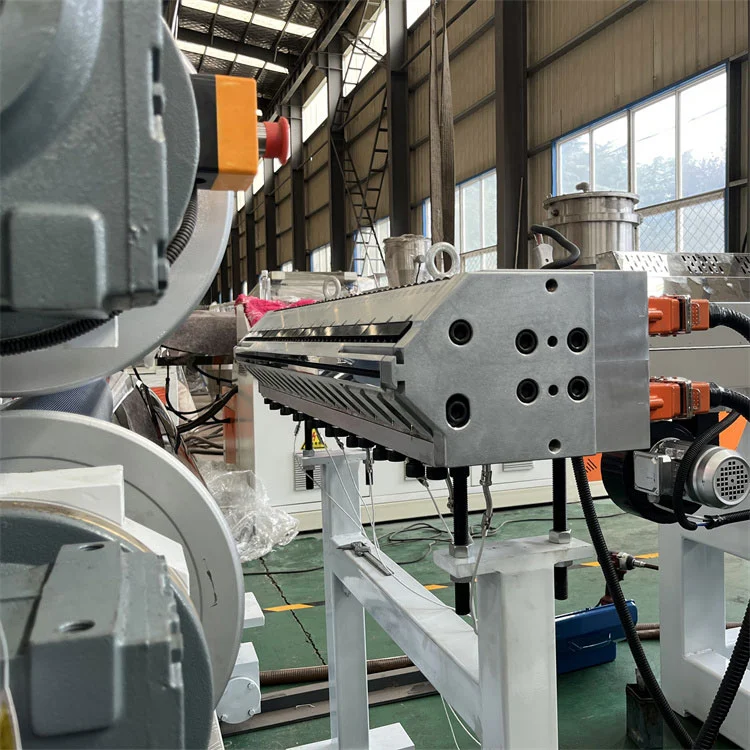

In the realm of advanced industrial machinery, the PVC Electrostatic Board Extruder Machine by Qingdao Eaststar Plastic Machinery Co., Ltd. stands as a pinnacle of innovation and reliability. Designed specifically for manufacturing high-quality PVC electrostatic boards, this machine transforms raw PVC compounds into durable, static-resistant panels used across various industries. Whether for cleanrooms, electronic manufacturing, or medical facilities, it ensures consistent performance, making it an indispensable asset for businesses aiming to elevate their production standards.

Imagine a production line where efficiency meets precision—this machine delivers exactly that. With cutting-edge extrusion technology, it guarantees uniform thickness, superior surface finish, and exceptional electrostatic properties. Users often report a significant reduction in material waste and downtime, leading to increased profitability and smoother operations. The emotional relief of knowing your production is in safe hands cannot be overstated; it solves the common frustrations of inconsistent output and frequent maintenance, replacing them with confidence and peace of mind.

What sets this extruder apart is its blend of robust construction and intelligent design. Crafted from high-grade materials, it withstands rigorous use while maintaining optimal performance. Key features include an advanced temperature control system for precise heating, an automated feeding mechanism that minimizes human error, and energy-efficient components that cut operational costs. Moreover, Qingdao Eaststar Plastic Machinery Co., Ltd. backs each unit with a comprehensive quality promise, ensuring long-term durability and support.

This machine is ideal for manufacturers, factory operators, and entrepreneurs in sectors like electronics, healthcare, and construction. Common scenarios include producing anti-static workbenches, partition walls, and flooring materials. For instance, in electronics assembly lines, it helps prevent static damage to sensitive components, while in hospitals, it supports hygienic, static-free environments. The versatility extends to small-scale workshops and large industrial plants, adapting seamlessly to varying production volumes.

Many businesses struggle with production inefficiencies, such as uneven board thickness or high rejection rates. The PVC Electrostatic Board Extruder Machine addresses these directly through its precision engineering. Below is a summary of key parameters that highlight its problem-solving capabilities:

| Issue | Solution | Parameter |

|---|---|---|

| Inconsistent thickness | Precision die design | Thickness tolerance: ±0.1mm |

| High energy consumption | Energy-saving motors | Power: 15-45 kW (adjustable) |

| Frequent maintenance | Corrosion-resistant parts | Material: Stainless steel key components |

| Slow production speed | High-speed extrusion screw | Output: 100-500 kg/h |

Unlike many competitors, this extruder integrates smart monitoring systems that provide real-time data on performance metrics. Its modular design allows for easy upgrades, future-proofing your investment. Additionally, the focus on user-friendly interfaces reduces training time, enabling quick adoption by teams. These elements combine to offer a unique value proposition that emphasizes not just functionality, but also adaptability and ease of use.

What is the typical lifespan of this machine?

With proper maintenance, the PVC Electrostatic Board Extruder Machine can operate efficiently for over 10 years, thanks to its durable construction and quality components from Qingdao Eaststar Plastic Machinery Co., Ltd.

How does it handle different PVC formulations?

It features adjustable settings for temperature, screw speed, and pressure, allowing it to process various PVC blends without compromising on board quality or electrostatic properties.

Is technical support available after purchase?

Yes, comprehensive support including installation guidance, troubleshooting, and spare parts supply is provided to ensure seamless integration into your production line.

Can it be customized for specific board sizes?

Absolutely, the machine can be tailored to produce boards in widths from 600mm to 1300mm and thicknesses from 1mm to 20mm, meeting diverse client requirements.

What safety features are included?

It comes with emergency stop buttons, overload protection, and insulated electrical systems to safeguard operators and equipment during operation.

Embrace a new era of manufacturing with a machine that not only meets but exceeds expectations. The sense of achievement when your products consistently pass quality checks is unparalleled, turning operational hurdles into milestones of success. By choosing this extruder, you invest in reliability, innovation, and a partnership with Qingdao Eaststar Plastic Machinery Co., Ltd., dedicated to your growth and satisfaction.