PE PP Sheet Extruder Machine,PVDF PEEK Sheet Extruder Machine,PA POM Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PE PP Board Extruder Machine,PVC Sheet Extruder Machine,PS Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,Biodegradable Sheet Machine

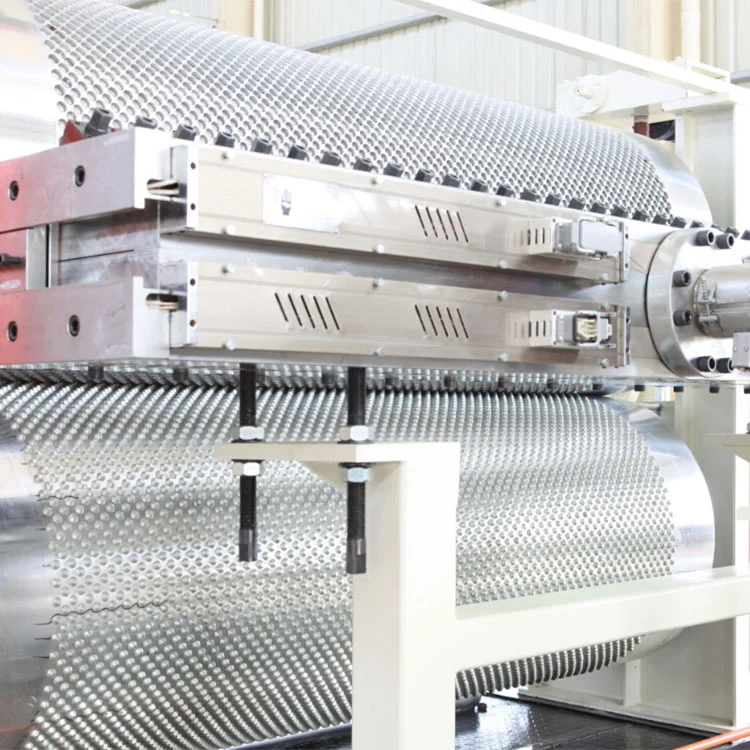

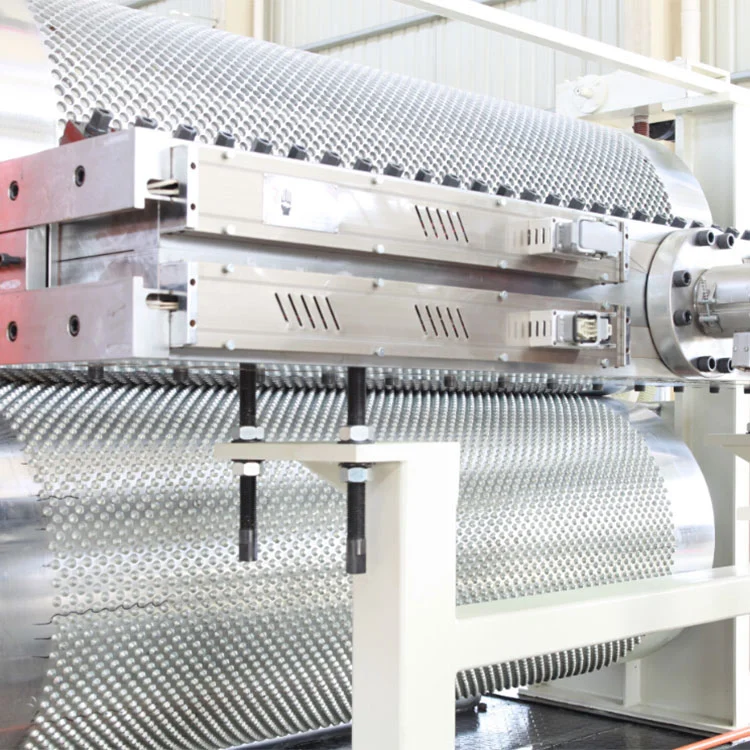

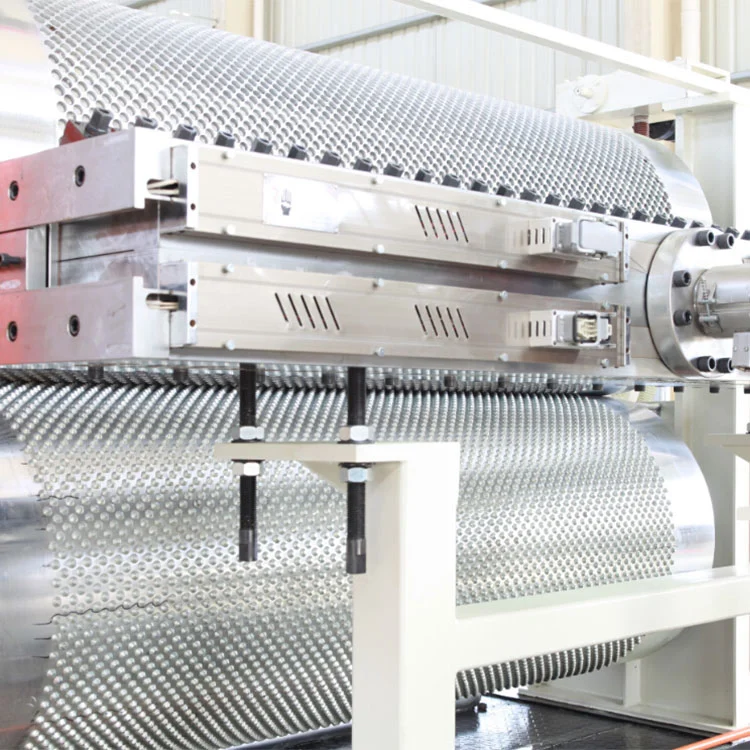

In the realm of construction and civil engineering, effective drainage systems are paramount to ensuring structural longevity and environmental safety. Qingdao Eaststar Plastic Machinery Co., Ltd. proudly presents the HDPE Drainage Board Extruder Machine, a revolutionary piece of equipment designed to manufacture high-density polyethylene (HDPE) drainage boards with precision and efficiency. These boards are essential components in geotechnical applications, providing reliable drainage, filtration, and protection in projects ranging from landfills and tunnels to green roofs and sports fields. By leveraging advanced extrusion technology, this machine enables the production of durable, lightweight, and eco-friendly drainage boards that meet global standards. Whether you're tackling large-scale infrastructure or residential developments, this machine empowers you to create solutions that stand the test of time and nature.

HDPE Drainage Board Extruder Machine in operation" style="max-width:100%; height:auto; margin:20px 0;">

HDPE Drainage Board Extruder Machine in operation" style="max-width:100%; height:auto; margin:20px 0;">

At the heart of the HDPE Drainage Board Extruder Machine lies a blend of innovation and reliability. One of its standout features is the utilization of premium-grade materials in its construction, ensuring long-term durability and resistance to wear. The machine incorporates cutting-edge extrusion technology, which allows for consistent output with minimal energy consumption. Its user-centric design includes intuitive controls and automated systems, reducing the need for extensive training and minimizing human error. Moreover, Qingdao Eaststar Plastic Machinery Co., Ltd. backs this product with a robust quality promise, including comprehensive warranties and dedicated technical support. This commitment translates into smoother operations, higher productivity, and peace of mind for businesses aiming to excel in the competitive plastics manufacturing industry.

The HDPE Drainage Board Extruder Machine caters to a wide array of professionals and sectors. Construction companies, civil engineers, and environmental consultants will find it indispensable for projects involving soil stabilization, water management, and erosion control. Typical usage scenarios include creating drainage layers in foundation walls, road embankments, and agricultural fields. For instance, in urban development, it helps prevent waterlogging in basements, while in landscaping, it supports healthy plant growth by facilitating proper aeration. By adopting this machine, users can address common challenges like material waste and inconsistent product quality, ultimately leading to more sustainable and cost-effective outcomes. It's an ideal choice for those who value efficiency, precision, and environmental stewardship in their operations.

Imagine the satisfaction of completing a project without the nagging worry of drainage failures or costly repairs. With the HDPE Drainage Board Extruder Machine, users experience a profound sense of reliability and achievement. It eliminates the frustrations associated with subpar drainage materials, such as clogging or degradation over time, by producing boards that offer superior flow capacity and longevity. This not only safeguards structures from water damage but also enhances the overall safety and aesthetics of the environment. Clients report feeling more confident in their deliverables, knowing that the machinery from Qingdao Eaststar Plastic Machinery Co., Ltd. delivers consistent, high-quality results that exceed expectations. It's not just about making products; it's about building trust and fostering positive change in communities.

What makes the HDPE Drainage Board Extruder Machine truly exceptional is its array of unique differentiators. Unlike conventional extruders, it boasts a modular design that allows for easy customization and upgrades, adapting to varying production needs without major overhauls. The integration of smart sensors and real-time monitoring systems ensures optimal performance and early detection of issues, reducing downtime significantly. Additionally, its energy-efficient motors and recyclable material compatibility align with green initiatives, setting it apart in an era focused on sustainability. Qingdao Eaststar Plastic Machinery Co., Ltd. has infused decades of expertise into this machine, resulting in a product that not only meets but anticipates market demands, offering a competitive edge through innovation and forward-thinking engineering.

To help you understand how the HDPE Drainage Board Extruder Machine addresses specific challenges, consider the following scenario: Many projects face delays due to inconsistent board thickness and low production rates. Our solution involves precision engineering that guarantees uniform output and high efficiency. Below is a table outlining key parameters for reference:

| Parameter | Specification |

|---|---|

| Extrusion Output | Up to 500 kg/h |

| Board Thickness Range | 8-20 mm |

| Power Consumption | Approx. 100-150 kW |

| Machine Dimensions | 6000x2000x2500 mm |

| Warranty Period | 2 years |

What types of raw materials can the HDPE Drainage Board Extruder Machine process?

This machine is specifically designed to handle high-density polyethylene (HDPE) materials, including virgin and recycled granules. It can also accommodate certain modified polymers for enhanced properties, ensuring flexibility in material sourcing while maintaining output quality. Qingdao Eaststar Plastic Machinery Co., Ltd. recommends using materials with consistent melt flow rates for optimal performance.

How does the machine ensure consistent board quality during production?

Through advanced PLC control systems and precision sensors, the extruder continuously monitors factors like temperature, pressure, and speed. This allows for real-time adjustments, minimizing variations in thickness and density. Regular calibration and automated feedback loops further enhance consistency, resulting in boards that meet stringent industry standards.

What maintenance routines are required to keep the machine running smoothly?

Routine maintenance includes daily cleaning of the extrusion die, weekly lubrication of moving parts, and monthly inspections of electrical components. The machine is designed for easy access to key areas, reducing downtime. Qingdao Eaststar Plastic Machinery Co., Ltd. provides detailed manuals and online support to guide users through these processes, ensuring long-term reliability.

Can the extruder be customized for specific production needs?

Yes, the modular design allows for customization in terms of output capacity, board dimensions, and additional features like color mixing or anti-static coatings. Clients can work with our engineering team to tailor the machine to their unique requirements, making it a versatile solution for diverse applications.

What safety features are integrated into the machine?

Safety is a top priority, with features including emergency stop buttons, thermal overload protection, and enclosed moving parts. The control panel also includes user-friendly interfaces with alert systems for abnormal conditions, ensuring a secure operating environment for all personnel.

How energy-efficient is the HDPE Drainage Board Extruder Machine compared to older models?

This model incorporates high-efficiency motors and optimized heating systems, reducing energy consumption by up to 20% compared to conventional extruders. This not only lowers operational costs but also supports environmental sustainability efforts, aligning with global green standards.